The first solution is a basic premise that has two joints, one at the head of the fixture and another in the middle, for turning ability. Its head is cylindrical and its shape provides a sleek and uniform appeal. The lens contours with the shape of the head to make a full circle.

Pros - sleek design

- adequate turning

- variability

Cons - complicated design

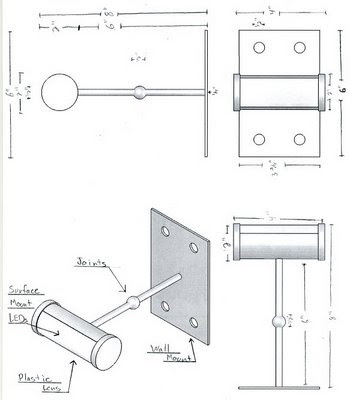

The second solution is similar to the first design except that the head is flattened at the lens to allow a different lighting angle. Also the joints are at the base of the head and at the connection of the back-plate to the fixture. This also allows for a sleek and uniform appeal to the industrial world.

Pros - Sleek design

- adequate turning

Cons - complicated design

The third solution is the more dissimilar of the other two. Its head is a lamp-like shape and makes for a circular lighting. There are also three joints in this design and it allows for various degrees of movement. This will also have LED lighting as the other two do.

Pros - great degree of turning

- simple design

Cons - unappealing design